My home is in the Northeast countryside , It's cold in winter , Bought a boiler , Need circulating pump . Simply put, the circulating pump starts automatically after the boiler water is hot , Then the hot water is conveyed away , To heating , The hot water is pumped away , Cold water enters the boiler , The temperature drops , The circulating pump is shut down , Wait for the next time the water is heated . Because the house that needs heating is far away from the place where the boiler is burning , So we need circulating pump , If the distance is close, the circulation will be automatically completed by using the principle of hot water upflow and cold water backflow after the water is heated . Of course, there are such devices on the market that use the temperature to automatically control the opening and closing of the circulating pump :

The principle is that there is a thermistor probe ( With magnet adsorption , It can be adsorbed on the boiler wall ), And then a relay controls . When the temperature reaches the set value , The relay is on , The circulating pump starts , The boiler wall temperature drops after circulation , Relay off , The circulating pump is shut down .

Circulating pump :

Because the circulating pump in my home has a large power , The small relay burned out after being started several times , So a layer of AC contactor is connected in the middle ( My old father added ).

This kind of equipment on the market can roughly solve the problem of water circulation , But there are also some details that cannot be solved , for example : When the water temperature of the return pipe also reaches the set temperature value , The circulating pump will always be on , At this time, you need to manually adjust the knob temperature ( Raise height ), Stop the circulating pump ( The high-power circulating pump consumes a lot of electricity ). And so on When the coal inside the furnace is gradually burned ( It is called waterlogging in Northeast dialect ), The boiler temperature does not reach the set value , At this time, it is necessary to lower the knob , Start the circulating pump , Let the residual temperature produced by these coals not be wasted .

Due to the above shortcomings , Someone needs to adjust the knob every few hours . This part of the work is done by my old father , So I want to make an automatic thing to reduce the workload of my old father .

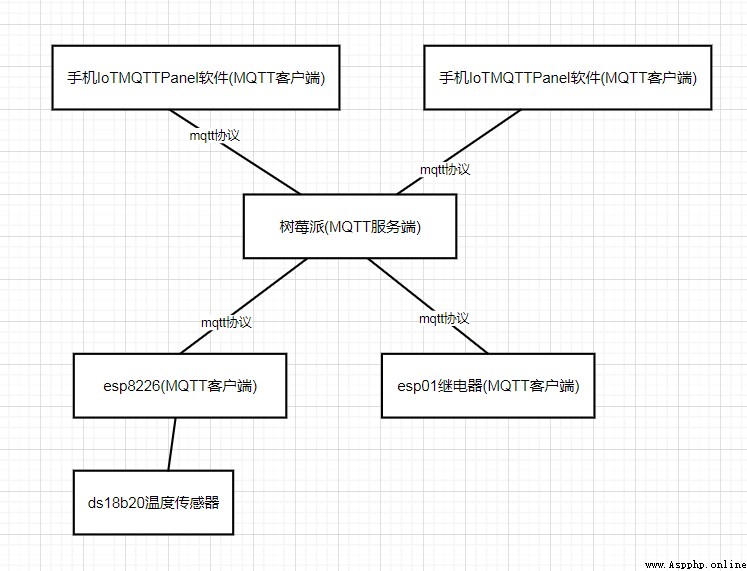

My original idea was that I could adjust the temperature remotely through my mobile phone , At least you don't have to adjust the knob manually , I get up in the middle of the night and use my mobile phone to adjust it . A structure designed based on the original idea :

esp01 modular + Relay module ,220v turn 5v modular + Insert = Networking socket

esp8226 + Temperature sensor + Nixie tube = Real time temperature detection and display networking module

My control system is written in esp8226 in .

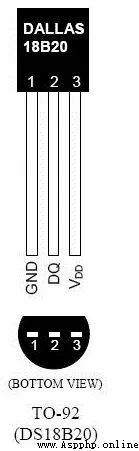

Temperature sensor probe fabrication : To drive ds18b20 sensor , Need to be on the data bus (DQ) And VDD Add a... Between the pins 4.7k Ohm resistance ( Pull up resistance ), This is a must , Wrap it with an iron button , There are two small neodymium magnets inside , Finally, fill it with good glue , This forms a temperature sensor probe , Can be adsorbed on the boiler wall :

I made a mistake in this step , take ds18b20 Both the sensor and the pull-up resistor are put into the probe , The temperature sensor fails to read the temperature when the temperature rises , It is because the resistance value increases with the increase of temperature . Later, I put the resistor in the tail to solve this problem .

Packaged probe :

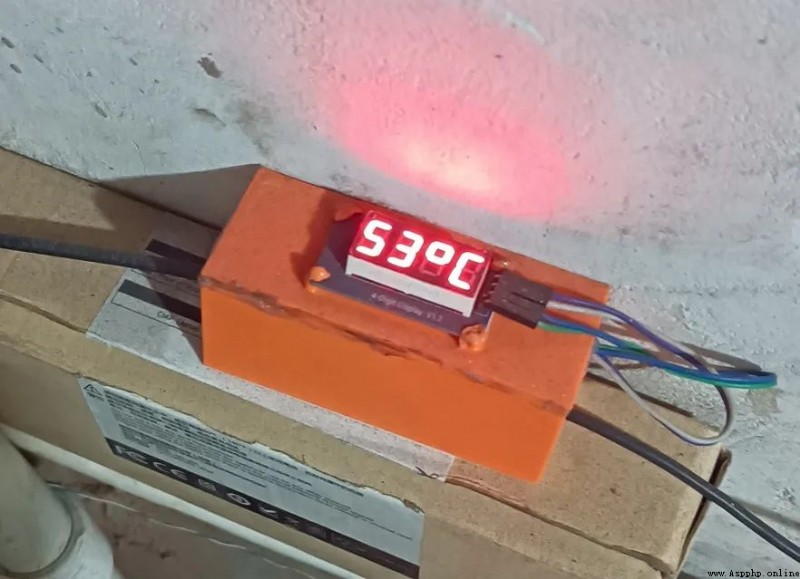

esp8226 + Nixie tube module :

The shell is for me 3D Printed by the printer , There's... In it esp8226 modular .

The firmware

esp8226 and esp01 I burn them all micropython The firmware .

signal communication

At the beginning of communication, I want to use socket Realization , Make it simple HTTP Protocol to communicate , But such control on mobile phones is troublesome , There is no easy-to-use software , I have to do a web Interface , in addition socket Blocking threads .

Then I found out MQTT This kind of agreement , This is a hardware network communication protocol for the Internet of things , Can cope with high latency network environment . A brief introduction MQTT agreement , First, you need a server ( There are also generations { too }{ filter } Manage the server , Running on a computer , Here I run on raspberry pie ), Then all your IOT hardware devices ( Such as esp8226) It's all clients , IOT hardware equipment ( client ) There will be no direct communication between , They all communicate directly with the server , If you need to communicate between hardware devices, you need to publish or subscribe to topics . for example : If the hardware A And hardware B We need to communicate with each other , So first they all need to be connected to Server side , then A Publish a project called topic The theme of , If the hardware B Accept A You need to subscribe topic This theme , That's it A ---> B Communication for , So reverse communication is also a principle ,B Release theme ,A Subscribe to . This agreement has another advantage , You can subscribe to multiple clients of a topic , In this way, multi terminal communication can be realized .mqtt In protocol communication, each client does not know the existence of other clients , They all communicate directly with the server .

mqtt The agreement micropython The firmware ( I don't know if the default firmware of Anxin also exists ) There is a big problem with communication :LmacRxBlk:1 Report errors . for example , If you subscribe to a topic at the beginning , Then you use a non blocking method check_msg() Handle through the callback function Subscribed topic messages , At this time, if you subscribe to more topics than you check_msg() The number of times , Then it will be in micropython An error is reported at the bottom of the firmware LmacRxBlk:1, Then the communication is interrupted , Simply put, you subscribe to a topic and enter the event loop , There is no time to process the message of the subscription topic , Will lead to this error . The official explanation for this mistake is tcp buffer Resources are not released , because esp8226 Available resources are very limited , But in mqtt In communication, I can't release the connection after every cycle , Then re - establish the connection each time , And the disgusting thing about reporting errors is ,try except It can't be captured , So the problem can only be solved by design , That is, to ensure that the published interval of the subscribed topic is far less than the cyclic interval , Ensure that the subscribed messages can be processed in time every time . I have solved this problem for a long time , because try except Can't capture , And not often , Unable to locate , I have no idea why the communication was interrupted .

Code core logic writing

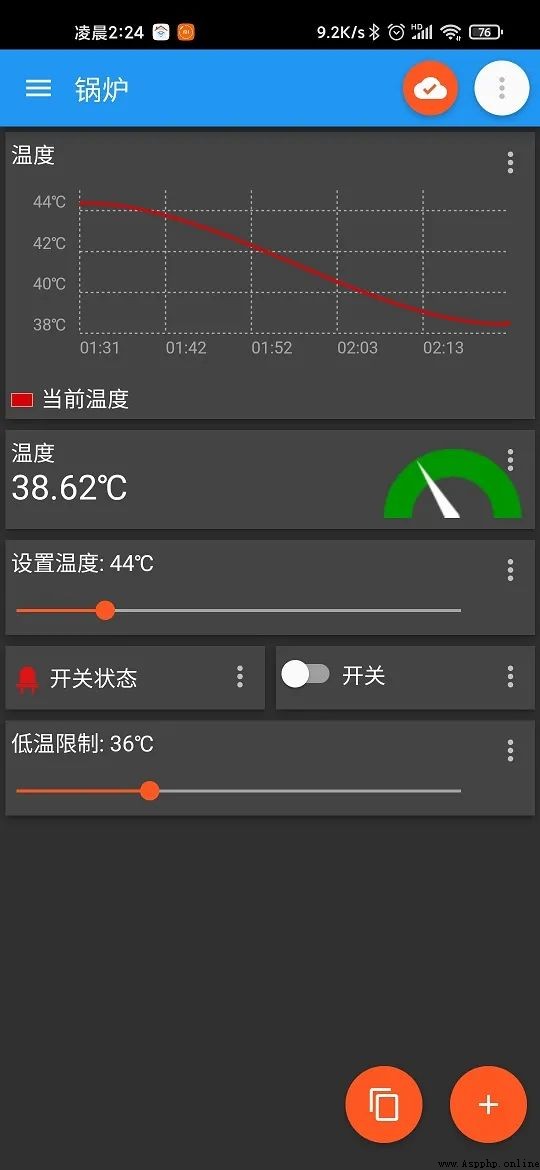

The core control logic I wrote in esp8226 Module , Cycle acquisition temperature , Then publish the temperature as a theme , The mobile phone can subscribe to the theme to view the boiler temperature in real time , There is one in the loop setting temperature The variable of , If the collected temperature is higher than setting temperature Then release a Switch theme Open theme , If the temperature is lower than setting temperature , Then release a Switch theme close , And every time you subscribe Set the theme , For modification setting temperature Variable .

esp01 Control relay , Every time you subscribe Switch theme That's all right. , And then every time The current state of the switch Publish as a theme .

I wrote this code logic at the beginning , You only need to publish and set the temperature theme on the mobile phone , But it also needs people to use their mobile phones to adjust for a period of time , Still can't realize automation , Later I revised it esp8226 Code logic in , It's a little complicated .

esp8226 The core logic is the same as above , The switch will be turned on after each detection temperature is higher than the set temperature , However, the switch will not be closed immediately if the temperature is detected to be lower than the set temperature after startup , Instead, wait for the detection temperature to be lower than the set temperature minus a variable, and then issue a switch off topic . This is to solve The detection temperature jumps repeatedly at the set temperature threshold , This will cause the switch to open and close repeatedly in a short time , A subtraction variable is introduced here , I call it Temperature step . There's a problem here , If the boiler keeps heating up , Then even if the circulating pump is always on , The boiler temperature will not be lower than the set temperature ( The temperature of the return pipe is higher than the set temperature ), Then the circulating pump will be always on , So here I introduce the second variable : Maximum startup time , I start a timer after each startup , If the timer time exceeds Maximum startup time , No matter whether the temperature is lower than setting temperature , Will shut down the circulating pump , And will setting temperature Improve , Increase the temperature to Temperature step Add the current temperature , Here we achieve Automatic adjustment setting temperature Of ( Lift direction ). There's another problem : When the coal in the furnace is burnt out , The temperature gradually decreases , The detected temperature will certainly be much lower than the set temperature , The circulating pump will never start . So here I introduce the third variable ( Callback detection time ), When esp8226 When powered on , Start a timer , If the timing time be equal to Callback detection time , It will be setting temperature Adjust to the current temperature , be used for setting temperature Automatic callback , hypothesis Callback detection time by 30 minute , So even setting temperature higher than Check the temperature , It's going to happen 30 Start the circulating pump in one minute , And residual logic to realize a closed loop , In this way... Can be achieved setting temperature , Up and down automatic adjustment . I also added a variable here Minimum temperature , If the current temperature is below Minimum temperature , So even if The current temperature is higher than setting temperature It will not start the circulating pump , Used when coal is not burned , This will prevent you from 30 Start the circulating pump every minutes , Minimum temperature Set it higher than the ambient temperature .

here setting temperature , Temperature step , Maximum startup time , Callback detection time , Minimum temperature , Can be set through the mobile terminal , I let esp8226 Subscribe to these topics to set these variables .

from machine import Pin,reset

import onewire

from ds18x20 import DS18X20

import time

import tm1637

from umqtt.simple import MQTTClient

def main():

client_id = "esp_temperature"

mserver = '192.168.0.99'

#mserver = '192.168.3.200'

#mserver = 'mq.tongxinmao.com'

tm = tm1637.TM1637(clk=Pin(14), dio=Pin(12))

ow=onewire.OneWire(Pin(4))

d = DS18X20(ow)

rom = d.scan()

def sub_callback(topic, msg):

# print((topic, msg))

nonlocal setTemperature

nonlocal lowTemperature

nonlocal startTime

nonlocal scanTime

nonlocal step

nonlocal startTimeTemp

nonlocal scanTimeTemp

nonlocal switchStatus

data = int(msg.decode())

if topic == b'setTemperature':

setTemperature = data

elif topic == b"setLowTemperature":

lowTemperature = data

elif topic == b"setStartTime":

startTime = data

startTimeTemp = startTime

elif topic == b"setScanTime":

scanTime = data*60

scanTimeTemp = scanTime

elif topic == b"setStep":

step = data

elif topic == b"switchWell":

switchStatus = data

else:

print(" error ")

def publishInfo():

nonlocal client

client.publish("setTemperatureR",str(setTemperature),retain=True)

client.publish("setLowTemperatureR",str(lowTemperature),retain=True)

client.publish("setStartTimeR",str(startTime),retain=True)

client.publish("setScanTimeR",str(int(scanTime/60)),retain=True)

client.publish("setStepR",str(step),retain=True)

client = MQTTClient(client_id, mserver, 0)

client.set_callback(sub_callback)

client.connect()

client.subscribe(b'setTemperature')

client.subscribe(b'setLowTemperature')

client.subscribe(b'setStartTime')

client.subscribe(b'setScanTime')

client.subscribe(b"setStep")

client.subscribe(b"switchWell")

showSet = True

setTemperature = 40

lowTemperature = 40

startTime = 120 # Starting time

scanTime = 1800 #30 minute

step = 7

switchStatus = 0 # 0 Means closing ,1 Open for indication

startTimeTemp = startTime

scanTimeTemp = scanTime

while True:

try:

d.convert_temp()

# Display temperature and set temperature

nowTemperature = d.read_temp(rom[0])

if showSet:

tm.temperature(int(setTemperature))

else:

tm.number(int(nowTemperature*10))

if int(nowTemperature) >= setTemperature and (not switchStatus) and int(nowTemperature) > lowTemperature:# Start above the set temperature

client.publish("switch",'1',retain=True)

startTimeTemp = startTime

if (int(nowTemperature) <= setTemperature - step) and switchStatus:

client.publish("switch",'0',retain=True)

if startTimeTemp <= 0: # If the time exceeds 3 minute , Auto stop , And increase the set temperature

client.publish("switch",'0',retain=True)

setTemperature = int(nowTemperature + step)

startTimeTemp = startTime

if switchStatus:

startTimeTemp -= 1

client.check_msg()

client.publish("temperature",str(round(nowTemperature,2)),retain=True)

publishInfo()

if scanTimeTemp <= 0:

setTemperature = int(nowTemperature - step) # Callback cooling

scanTimeTemp = scanTime

scanTimeTemp -= 1

except Exception as e:

reset()

time.sleep(1)

showSet = not showSetesp01 In the code :

from machine import Pin

from umqtt.simple import MQTTClient

import time

def main():

def sub_callback(topic, msg):

nonlocal client

nonlocal pin

"""

Receive subscription message callback

"""

if msg == b'0':

pin.off()

else:

pin.on()

client.publish("switchWell",str(pin.value()),retain=True)

client_id = "switch_id"

mserver = '192.168.0.99'

#mserver = 'mq.tongxinmao.com'

pin = Pin(0,Pin.OUT)

client = MQTTClient(client_id, mserver, 0)

client.set_callback(sub_callback)

client.connect()

client.subscribe(b'switch')

while True:

client.check_msg()

client.publish("switchStatus",str(pin.value()),retain=True)1. Mobile terminal :

MQTT Dash:

IoTMQTTPanel:

On the mobile phone, I still recommend IoTMQTTPanel, Because it is very convenient to publish the configuration of one panel to another mobile phone , Just publish a topic , Then the receiving end can publish the whole panel by subscribing to a topic with the same name .MQTT Dash It also has this function , But it will get stuck after the release , do not know why .

2. Computer terminal :

I don't know what software is available on the computer , So I use it PyQt5 Simply write a monitoring software , No adjustment function , Because the equipment was not very stable at that time , So I have been monitoring the running status .

at present , The whole thing has been running steadily for two weeks , There is no need for people to adjust . I've been doing it over and over for a long time , To solve all the problems , Especially the LmacRxBlk:1 Report errors , It took me a long time . It's still very difficult to make something useful from scratch , Because some problems can only be exposed through the actual environment , For example, when the pull-up resistance is heated up, the resistance value changes . There are many details I haven't mentioned , For example, burning firmware ,3d Modeling shell ,mosquitto Service deployed on raspberry pie , Port forwarding , There are too many contents to repeat , Only the main content and logic can be briefly described .

Official account :Python Source code

Get full code